Converting Juice into powder can be a solution for long shelf life and easy packing and transportation.

Converting Juice into powder can be a solution for long shelf life and easy packing and transportation.

SSP offers juice powder processing plants of various capacity to suit the client requirement.

The study, design & manufacturing of this processing line are the result of many years of efforts devoted to the research of processing methods focused on preserving the organoleptic, physical and aromatic characteristics of the processed fruit in order to produce a juice of high quality in color and clearness.

The study, design & manufacturing of this processing line are the result of many years of efforts devoted to the research of processing methods focused on preserving the organoleptic, physical and aromatic characteristics of the processed fruit in order to produce a juice of high quality in color and clearness.

Fresh juices are best in taste and color and are best to be consumed fresh. The efforts to preserve them & to ensure their quality, various techniques are to be adopted. This includes various process and preservation methods. The most important aspect is to ensure such methods which helps to retain these properties to the maximum extent.

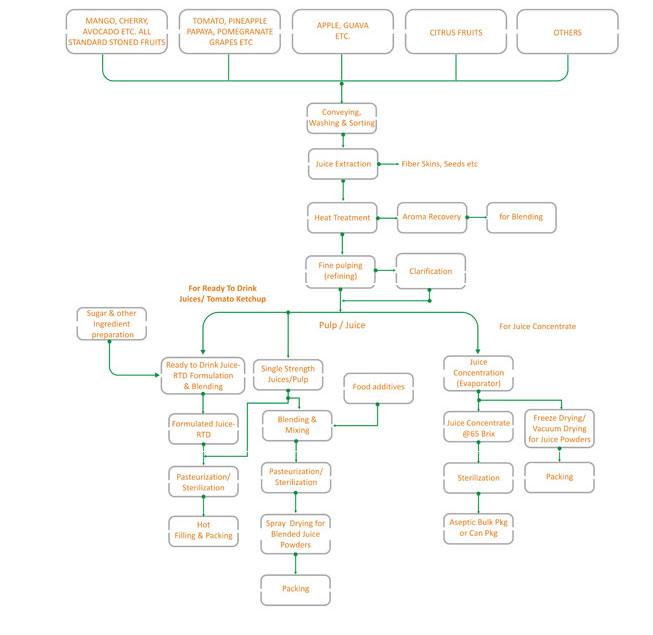

SSP offers complete line for fruit processing and concentration. This plant is for processing of fruits like mango, orange, apple, pears, etc. and for making juice concentration, paste, jam, jelly, ketchup, etc.

The plant size ranges between 1 Ton/day to 200 Ton/day or even more depending on availability of fruits.

THE MOST IMPORTANT STEPS INVOLVED IN PROCESSING OF JUICES AND BEVERAGES ARE:

- Selection and preparation of fruits

- Extraction of Juices

- Straining, Filtration and clarification

- Blending Pasteurisation.

- Filling, Sealing and sterilization

- Cooling, Labelling and Packing

For economic transportation of Fruit Juice concentrates and reduction of volume, two third of the water from the juice is extracted through evaporation process & the resultant concentrate is transported to factories, where the same amount of water or vitamin contents that was extracted before, is again added back or reconstituted. The process is called the Fruit Juice Reconstitution System.

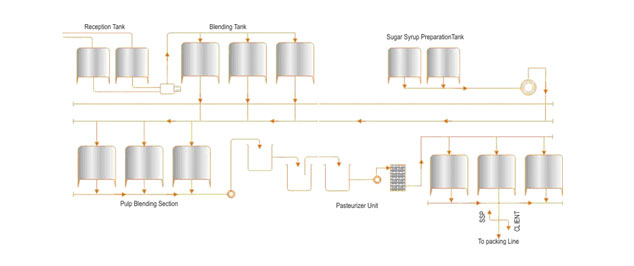

Unloading of paste from aseptic drums into a tank with a agitator.

Transfer of paste to a formulation tank where the other ingredients are added for dilution.

The formulation can be done for tomato juice, puree and ketchup. For juice and puree the dilution will take place in the formulation tanks and passes through the pasteurizer before filling and packing is done.

For ketchup preparation, sugar desolation and other ingredients will take place in separate tank. These ingredients are pumped to the blending tanks where the paste / puree is already in place. Heat in supplied through steam in the Jacket and all the ingredients are processed to confirm the ketchup requirements. The formulated ketchup is then pasteurized and packed into paper packet/ glass bottles.

Fruit Juice Powder Plant

Fruit Juice Powder Plant Converting Juice into powder can be a solution for long shelf life and easy packing and transportation.

Converting Juice into powder can be a solution for long shelf life and easy packing and transportation.

The study, design & manufacturing of this processing line are the result of many years of efforts devoted to the research of processing methods focused on preserving the organoleptic, physical and aromatic characteristics of the processed fruit in order to produce a juice of high quality in color and clearness.

The study, design & manufacturing of this processing line are the result of many years of efforts devoted to the research of processing methods focused on preserving the organoleptic, physical and aromatic characteristics of the processed fruit in order to produce a juice of high quality in color and clearness.